PRODUCTION

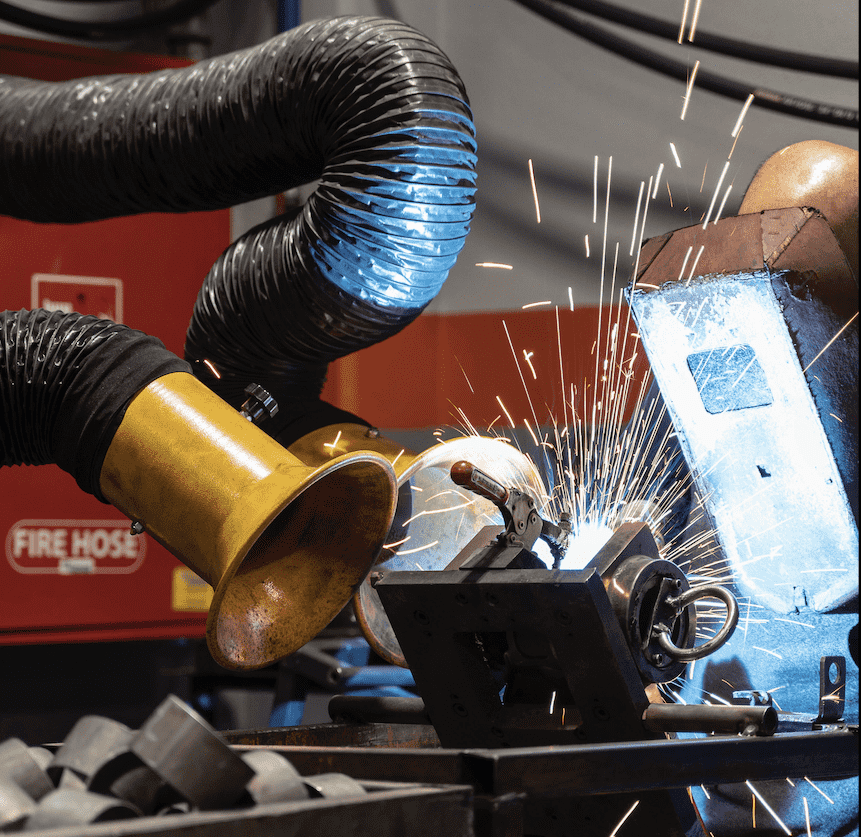

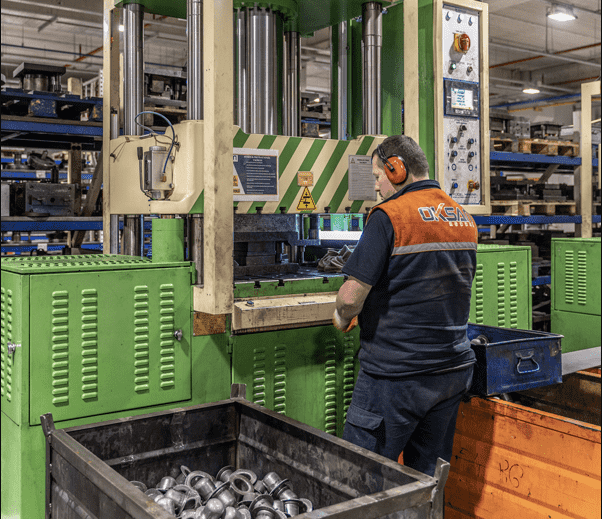

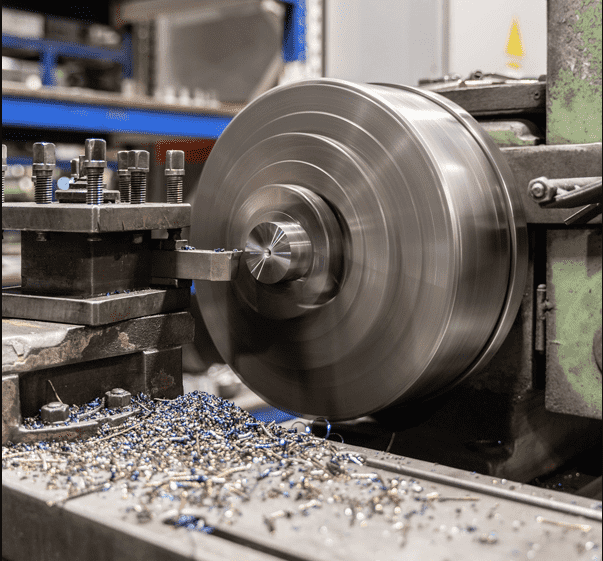

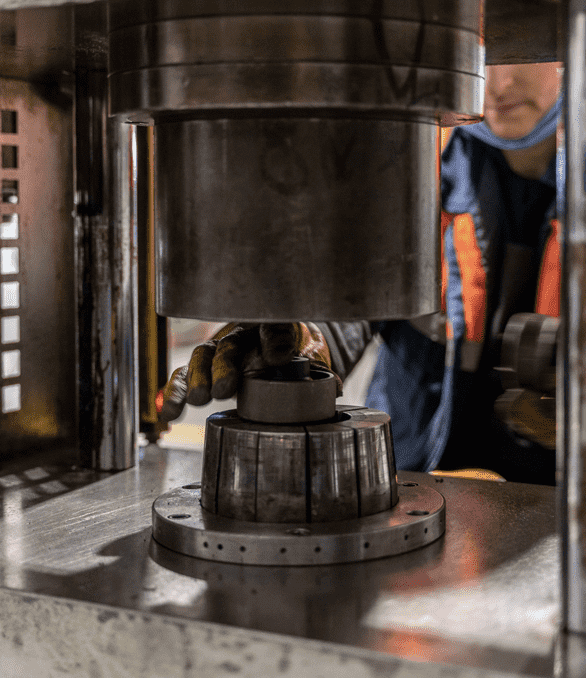

Oksan production takes place in each line with the same quality standardization. In all lines latest technology machines are used and quality targets are laid out in entire follow-up in a stable manner. High quality and manufacturing totality approach is targeted forever in our: Tooling, Vulcanization, Welding, Metal Forming, Machining, Rubber Dough Facility, Rubber – Metal Adhesive Application Facility, Metal Surface Operations Facility, Assembly & Finishing, Warehouse & Delivery.